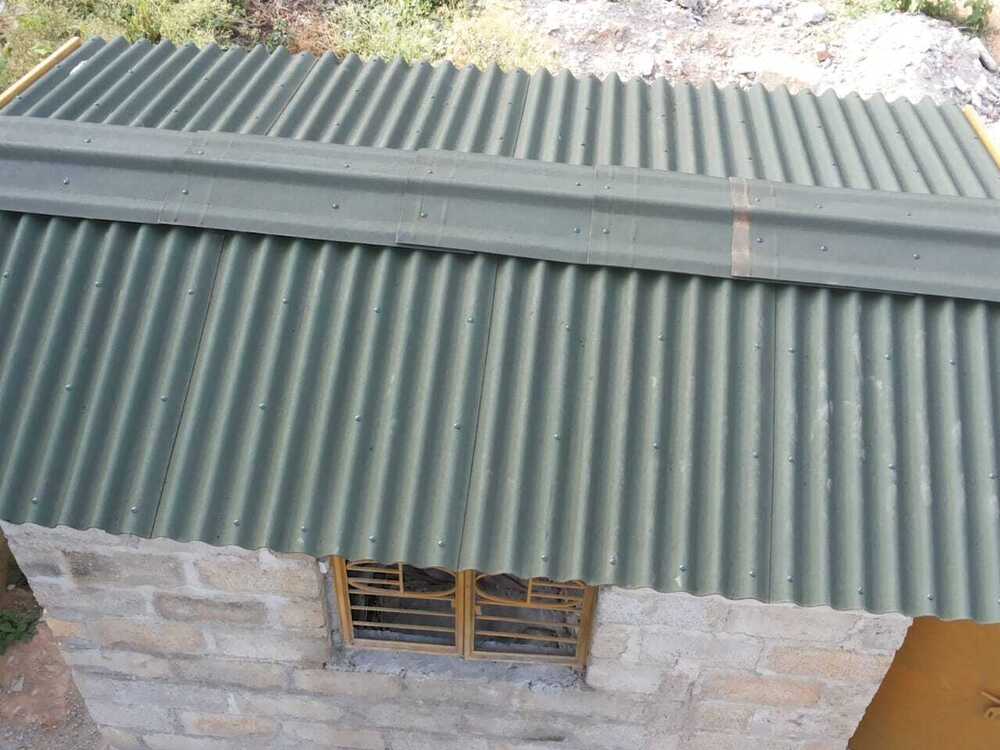

Roofing Shed

Price 1250 INR/ Sheet

Roofing Shed Specification

- Roof Material

- Steel Sheet

- Technics

- Cold Rolled

- Features

- Waterproof, Durable

- Usage & Applications

- Industrial, Warehouse, Commercial, Temporary Storage

- Height

- As per requirement

- Surface Treatment

- Color Coated

- Material

- Pre-painted Galvalume steel

- Tile Material

- Steel

- Tile Type

- Corrugated

- Type

- Roofing Shed

- Size

- Customized

- Shape

- Rectangular

- Pattern

- Ribbed

- Heat Transfer Coefficient

- Low

- Thickness

- 0.45 - 0.50 mm

- Length

- Up to 12 m

- Width

- 1000 mm (Effective Cover)

- Light Transmission

- Can be fitted with transparent sheets

- Corrosion Resistance

- Excellent

- Portability

- Relocatable as per site conditions

- Maintenance

- Low

- Life Span

- 20-30 years

- Insulation

- Can be provided with PUF/EPS sheet

- Wind Load Resistance

- Up to 170 km/h

- Modular Design

- Expandable/Customizable

- Accessories

- Gutter, Ridge, Flashing, Downspout available

- Installation Method

- Bolted/ Welded joints

- Environment Suitability

- Suitable for all weather conditions

- Color Options

- Available in Blue, Grey, Red, and customized colors

- Fire Resistance

- High

Roofing Shed Trade Information

- Minimum Order Quantity

- 10 Sheets

- Payment Terms

- Cash Advance (CA)

- Main Domestic Market

- All India

About Roofing Shed

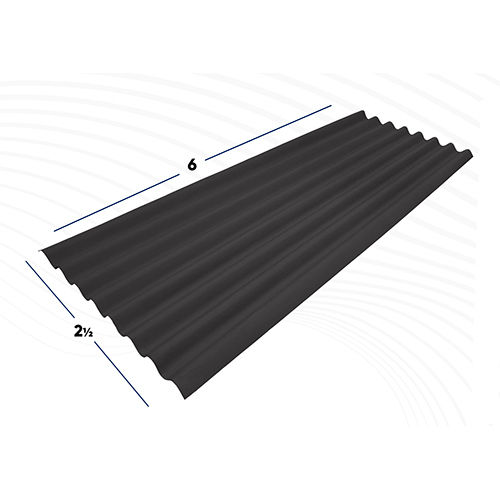

About Skylanes Asphalt Roofing Sheets

Skylanes Asphalt Roofing Sheets are the perfect roofing solution they are eco-friendly have a long life and are an economical solution for roofing and wall coverings. The sheets are available in several colours and are particularly aging-resistant, formaldehyde-free, and environment-friendly product. Made with paper waste combined with bitumen under intense pressure and heat they have excellent weather properties. The color pigments used in the sheets have excellent retention properties even under extremely sunny conditions. They are lightweight, easy to install, and can withstand all types of weather conditions. Suitable for tropical areas because they do not rust or corrode. They also absorb noise and heat making them ideal for hot regions and areas that are affected by heavy rains. Skylanes Asphalt Roofing sheets can be used both on new structures and for renovation work, on wood or metal structure. They are available in several colors to suit many applications. Skylanes Asphalt Roofing Sheets have proven to survive extreme temperatures, heavy rainfall, cyclones, storms, etc. during heavy winds, they guarantee protection due to their light weight properties by not falling and harming people or damaging property. As opposed to other roofing sheets, Skylanes Asphalt Roofing sheets drastically minimize rain noise. They're also an effective roofing solution to reduce heat, as this product has the inherent capacity to reduce high temperatures. It is an inexpensive option in comparison to other Roofing sheets considering all the features it possesses.

Superior Weather Resistance and Durability

Designed using pre-painted Galvalume steel, this roofing shed withstands all weather conditions. Its high fire and wind load resistance capabilities protect your assets year-round, while a long-lasting surface treatment prevents corrosion even in challenging environments. The low heat transfer coefficient ensures comfortable interiors, and minimal maintenance is required to keep the system performing at its best.

Flexible Customization and Installation

Tailor the shed to your needs with a wide selection of colors, thicknesses, lengths (up to 12 meters), and widths. The modular structure supports future expansion, and the shed's portable design allows relocation as your site requirements change. Installation is quick and secure, using either bolted or welded joints, making it suitable for projects across India.

Versatile Applications and Practical Accessories

Ideally used in industrial, warehouse, commercial, or temporary storage projects, this roofing shed meets a broad spectrum of application needs. Enhance performance by adding practical accessories like gutters, ridge capping, flashing, and downspouts. For natural illumination, transparent sheets can be integrated seamlessly into your roof design.

FAQ's of Roofing Shed:

Q: How is insulation provided in the roofing shed to regulate temperature?

A: Insulation for the roofing shed can be integrated using PUF (Polyurethane Foam) or EPS (Expanded Polystyrene) sheets. These materials offer superior thermal resistance, minimizing heat transfer and keeping the internal environment comfortable year-round.Q: What color options are available, and can I request a custom shade?

A: The roofing shed comes standard in blue, grey, and red. However, if you require a unique look, customized color options are also available to match your branding or project specifications.Q: When should I consider installing transparent sheets in the roof?

A: Transparent polycarbonate sheets can be fitted during installation if you need natural light in your facility. This is ideal for warehouses and work areas where daylight can reduce energy costs and improve visibility.Q: Where can these roofing sheds be used effectively?

A: These sheds are suitable for a wide range of environments across India, from industrial and commercial buildings to warehouses and temporary storage units, thanks to their all-weather and corrosion-resistant features.Q: What is the typical process for installing this roofing shed?

A: Installation involves assembling the modular prefabricated steel components on-site, using either bolted or welded joints. Accessories like gutters and downspouts can be added as needed. The process is streamlined for efficiency and minimal disruption.Q: How does the modular design benefit my project's future expansion plans?

A: The modular structure allows you to easily expand or reconfigure the shed to accommodate changing storage or workspace needs, making it a versatile, long-term solution for growing operations.Q: What maintenance is required for this roofing shed over its lifespan?

A: Minimal maintenance is required due to the shed's high-quality, corrosion-resistant materials and advanced surface treatments. Regular inspections and occasional cleaning are usually sufficient to ensure durability over 20-30 years.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Corrugated Sheets Category

Roofing Ridges

Price 600 INR / Sheet

Minimum Order Quantity : 10 Sheets

Shape : Curved

Thickness : 1722 mm

Type : Roofing Ridge

Width : 250 mm

Industrial Shed

Price 1450 INR / Sheet

Minimum Order Quantity : 100 Sheets

Shape : Rectangular

Thickness : 615 mm

Type : Industrial Shed

Width : As per requirement

Poultry shed

Price 1250 INR / Sheet

Minimum Order Quantity : 10 Sheets

Shape : Rectangular

Thickness : Roof Sheet: 35 mm

Type : Prefabricated Poultry Shed

Width : Custom (up to 40 feet or as per requirement)

Skylanes Vintage

Minimum Order Quantity : 100 Square Foots

Shape : Rectangular

Thickness : 1.5 Millimeter (mm)

Type : Skylanes Vintage

Width : 0.75 m / 2 ft Foot (ft)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry